Introduction:

(steam engine dunmow) Dunmow, a quaint town nestled in Essex’s serene landscapes, holds within its history a narrative of industrial metamorphosis catalyzed by the advent of the steam engine. During the 18th century, when the world was experiencing an unprecedented technological awakening, Dunmow became a microcosm of transformation due to the revolutionary implications of steam power. This article delves into the profound impact of the steam engine on Dunmow, unraveling its influence across industries, transportation, society, and its enduring legacy.

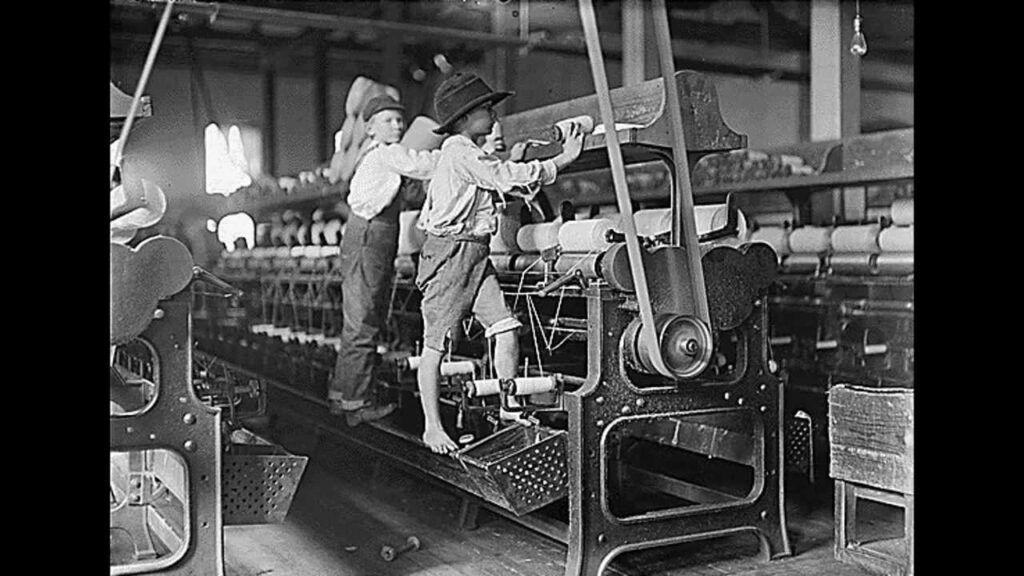

Industrial Revolution in Dunmow:

The introduction of steam power in Dunmow sparked an industrial revolution, reshaping the town’s economic landscape. Factories sprung up, harnessing steam-driven machinery to enhance production capacities across various sectors. Textile manufacturing underwent a radical transformation, significantly increasing output while reducing labor-intensive processes.

Agriculture, the backbone of Dunmow’s economy, experienced a revolution of its own. Steam-powered machinery revolutionized farming practices, boosting productivity and changing the dynamics of rural life. This shift not only increased crop yields but also altered the socio-economic fabric by reducing dependency on manual labor.

Transportation and Connectivity:

The impact of the steam engine on Dunmow’s transportation sector was monumental. The development of railway networks linked Dunmow to distant regions, revolutionizing trade and travel. Railway stations became bustling hubs, facilitating the movement of goods and people, fostering economic growth, and strengthening connections with neighboring towns and cities.

Components and accessories of steam engines

- Boiler: The heart of a steam engine, the boiler generates steam by heating water. It’s a sealed container where water is heated to produce high-pressure steam. The steam produced in the boiler is then used to power the engine.

- Steam Cylinder: This is where the power of steam is harnessed. The high-pressure steam from the boiler is directed into the steam cylinder, where it expands, pushing a piston back and forth. This reciprocating motion is converted into rotational motion.

- Piston: A piston is a cylindrical component inside the steam cylinder. It moves back and forth due to the pressure of the steam. Its movement is connected to a crankshaft or other mechanisms to convert linear motion into rotational motion.

- Valves: Valves control the flow of steam into and out of the cylinder. They regulate the admission of steam into the cylinder for the power stroke and release the used steam during the exhaust stroke.

- Condenser (optional): In some steam engine designs, a condenser is used to convert used steam back into water to be recycled into the boiler. This improves efficiency by reducing the amount of fresh water required.

- Governor: A governor controls the speed of the engine by regulating the supply of steam. It maintains a constant speed by adjusting the engine’s throttle based on its current speed.

- Flywheel: A large, heavy wheel attached to the crankshaft. It helps maintain the engine’s rotational momentum and smooths out variations in speed caused by the power strokes.

- Pressure Gauge and Safety Valve: The pressure gauge measures the pressure of steam within the boiler. A safety valve is crucial to prevent excessive pressure build-up, releasing steam if the pressure exceeds safe limits.

- Piping and Fittings: Various pipes and fittings transport steam from the boiler to the steam cylinder and return used steam to the condenser or atmosphere. These components need to be well-maintained to ensure proper steam flow.

- Lubrication System: Steam engines require proper lubrication for smooth operation. Lubricants are applied to various moving parts to reduce friction and wear.

- Control Mechanisms: Levers, handles, and controls are used to manage the engine’s operation, allowing operators to regulate speed, direction, and other functions.

- Insulation and Safety Features: Insulation materials help retain heat within the boiler and pipes, improving efficiency. Additionally, safety features like protective guards and warning systems are essential for safe operation

Societal Transformations:

The influx of employment opportunities in factories and mills led to a demographic shift as individuals from rural areas migrated to Dunmow in search of work. This transition from an agrarian society to an urbanized community redefined social structures and cultural dynamics, shaping a new way of life for its inhabitants.

Challenges and Environmental Impacts:

While the steam engine propelled Dunmow into an era of progress, it also brought forth challenges. The heavy reliance on coal as a primary fuel source led to environmental degradation, contributing to pollution and deforestation. The resulting environmental consequences posed health hazards and demanded a reevaluation of sustainable practices.

Legacy and Modern Relevance:

The legacy of the steam engine remains embedded in Dunmow’s identity. Museums and historical sites pay homage to this transformative period, showcasing the evolution of steam-powered machinery and its profound impact on the town’s development. Lessons learned from this era serve as a blueprint for responsible technological advancement and environmental stewardship in the present day.

Preserving Dunmow’s Industrial Heritage:

Dunmow continues to honor its industrial heritage, embracing technological advancements while also acknowledging the importance of preserving historical landmarks. Efforts to conserve artifacts, documents, and machinery from the steam era serve as a reminder of the town’s journey through industrial transformation.

Looking Ahead:

As Dunmow navigates the challenges of the 21st century, it stands at the crossroads of innovation and sustainability. Embracing renewable energy sources, fostering innovation, and promoting eco-friendly practices reflects the town’s commitment to a progressive future while respecting its rich industrial past.

Conclusion:

The steam engine’s impact on Dunmow was not merely a chapter in history but a pivotal turning point that shaped the town’s trajectory. Its influence on industries, transportation, society, and the environment echoes through time, leaving an indelible mark on Dunmow’s identity. Recognizing its legacy is pivotal in understanding the profound implications of technological advancements and the imperative of sustainable progress for generations to come.